This complete documentation not only serves as a document of compliance but additionally becomes Digital Trust an invaluable resource for future maintenance and audits. By digitizing these processes, producers can streamline audits, cut back paperwork, and enhance regulatory compliance. Digital documentation permits for simple access and traceability, simplifying collaboration among stakeholders. This approach ensures the equipment could be tracked and evaluated throughout its lifecycle, finally improving effectivity, lowering prices, and enhancing total product high quality. Factory acceptance testing (FAT) is a strategy of testing tools or systems on the manufacturer’s facility before it is delivered to the client. The function of FAT is to confirm that the gear meets the customer’s necessities and is ready for set up and use.

What Is Factory Acceptance Testing – Benefits, Course Of, Types

The Factory Acceptance Test is efficacious for both end-users and manufacturers. It ensures the brand new gear meets all agreed-upon specs, stopping issues on the client’s web site. Fixing manufacturing issues before the equipment leaves the producer helps control the project’s timeline and budget what is factory acceptance testing. The FAT is a cheap answer, most popular over addressing points after deployment.

When Is The Most Effective Time To Schedule An Fat?

Testers use acceptance criteria to confirm if the feature behaves as intended. It makes testing faster and more accurate, as testers know exactly what to verify. No matter how technically brilliant your software program is, if it doesn’t meet user wants, it’s destined for the digital dustbin.

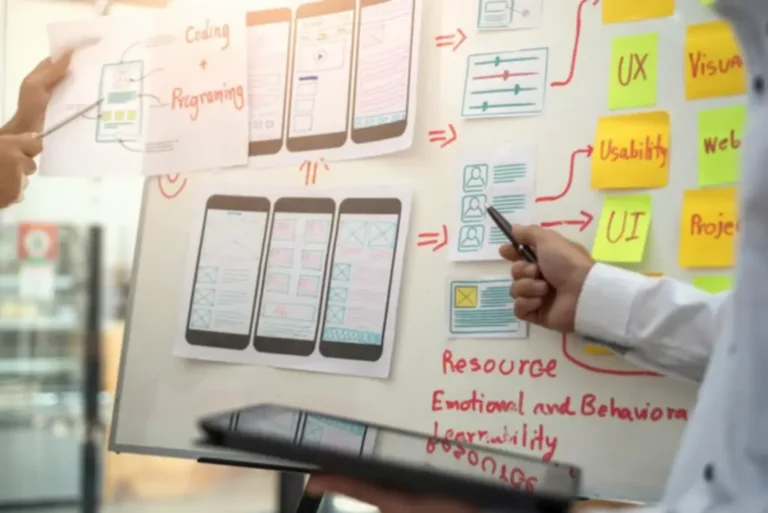

Software For Manufacturing Unit Acceptance Testing

Common standards embrace ISO 9001 for quality administration systems and ASTM or ASME standards for mechanical gear. Industry-specific standards and regulations like FDA rules for medical units or ASME B31.three for piping systems may also apply. Our function is to make certain that the related requirements are met before your product leaves your factory. Factory Acceptance Testing (FAT) is a take a look at carried out for newly manufactured and packaged equipment by the seller prior to transport to ensure the equipment meets its supposed objective. This elective test is carried out once the design and fabrication of the equipment are complete following accredited take a look at plans as agreed with the shopper.

Tips About Tips On How To Create Top-tier Acceptance Criteria

An skilled companion will understand the distinctive challenges and requirements of your sector, enabling them to provide tailor-made options. Check their observe report and ask for case studies or references from similar tasks. Furthermore, profitable FAT results can serve as a robust marketing software, demonstrating the item’s robustness and reliability.

This proactive strategy minimizes the risk of pricey recollects and reinforces shopper belief in the product’s reliability and high quality. One of the most significant advantages of conducting the FAT on the manufacturer’s web site is the power to offer immediate decision to any points or defects uncovered during testing. The Factory Acceptance Test (FAT) is a rigorous analysis carried out on equipment or machinery to make certain that it meets predefined specs and performs as supposed before it’s shipped to the shopper. Essentially, it’s a last high quality assurance step earlier than the product leaves the factory ground. Once all of the recognized issues are resolved and retested, it’s time for the final review. Key stakeholders will evaluate the check outcomes and supply their sign-off.

This provides a roadmap on your testers and sets expectations for what needs to be completed. Clearly documented aims assist everybody keep centered and ensure the testing course of aligns together with your overall project objectives. This additionally facilitates better communication between technical groups and end-users, minimizing misunderstandings and streamlining the testing process. FATs are useful not just for the buyer and end users but for the producer as well. Both events can be assured that the equipment meets all of the contractual specifications and any issues may be addressed before arriving at the customer’s site.

This helps units your expectations to the producer and they will remember to embrace the related checks in your checklist. The problem of dealing with issues when equipment is constructed and operated the primary time round can be a large headache if you’re the one with the task of installation and start-up. Wouldn’t or not it’s good to get some reassurance previous to receiving your equipment? Conducted at the manufacturer’s site prior to delivery and installation, these exams assist to establish any issues and correct them prior to cargo. Basically, an FAT is a “factory debug” to guarantee that when the system arrives on web site, it ought to have the ability to be installed and get up and working shortly and easily.

By following best practices and leveraging advice, producers can successfully implement automation in their FAT processes, driving growth and maintaining high requirements of high quality. This course of is essential for manufacturers trying to save prices, scale their operations, and preserve high requirements of manufacturing. In this comprehensive guide, we will delve into the intricacies of FAT, its significance in automation, and tips on how to choose and justify the best automation expertise. FAT documentation performs a significant role in recording check outcomes, figuring out any points, and assuring the client that the equipment meets all specifications and the customer’s necessities.

A Factory Acceptance Test is a test that runs on the equipment or elements before they are delivered to their intended vacation spot. While FATs can use simulations to show how the gear will operate in its future operating surroundings, it could be troublesome to imitate the actual working circumstances. These commonly take the type of a structured table, with each line merchandise being a check, with its own acceptance standards which have to be reviewed and signed off before moving to the subsequent part of the test plan. Incorporate User Acceptance Testing (UAT) standards alongside the dev team’s criteria. This offers you perception into how well the characteristic or app meets usability wants.

Since the aim of an FAT is to qualify the tools prior to shipment, it should never be conducted at the customer’s facility. Regularly evaluation and refine your automated FAT processes to make sure they continue to be environment friendly and effective. This could involve updating software program, including new options, or re-evaluating check procedures. Begin with a pilot project to test the feasibility and benefits of automation in your FAT process. This permits you to identify any potential challenges and make needed changes before scaling up. ‘Conventional management strategies encounter inherent limitations, similar to bottlenecked effectivity, inconsistency, and limited scope.’.

Verify pressure, temperature and materials information on the National Board nameplate to be according to specifications/P&ID and make sure presence of ASME “U” stamp. Times can differ depending on the complexity of the system and the corresponding FAT, but they are usually scheduled 2-4 weeks previous to the ship date to help keep on-time delivery. The period of the FAT may be wherever from in the future as much as a few weeks. Invest in coaching on your workers to ensure they are comfy with the model new technology and might use it effectively. Protecting your model from unfavorable evaluations and unhealthy customer experiences.

The primary accountability falls to a couple key roles, but others can add enter to ensure the standards are clear and useful. This ensures stakeholder expectations align with the delivered functionality earlier than final deployment. Business Acceptance Testing (BAT) focuses on validating that the software aligns with enterprise processes, objectives, and workflows. This testing confirms that the solution supports key business operations and delivers anticipated value. Your automation needs could develop over time, so it’s important to choose a companion that may scale their options to accommodate your future requirements. Ensure they’ve the capability to expand their providers as your operations develop.

- Ensure that the associate has the mandatory technical expertise to deal with your automation needs.

- This then requires information inputs from people, to document testing outcomes.

- Through a comprehensive understanding of FAT, producers can streamline their operations, mitigate potential dangers, and ultimately ship sturdy, high-quality gear to their clients.

- The course of should comprise testing as many features as possible in the manufacturing facility.

- By testing the tools or components before the customer receives them, DXP can enhance the odds that new installations will perform as anticipated.

Each take a look at course of ought to be explained in a sequential sequence, i.e., the way to check the hardware and software program. The needed expertise required by testers are defined in the means of planning. It is typically recommended that take a look at people with relevant expertise are selected for the intended application of the method, and safety devices are used to cope with the FAT plan.

Transform Your Business With AI Software Development Solutions https://www.globalcloudteam.com/ — be successful, be the first!